By Trey Ratcliff/StuckinCustoms.com

Not long ago I was waiting for a domestic flight in a departure lounge at one of the crumbling midcentury sheds that pass for an American airport these days. There were delays, as we’ve all come to expect, and then the delays turned into something more ominous. The airplane I was waiting for had a serious maintenance issue, beyond the ability of a man in an orange vest to address. The entire airplane would have to be taken away for servicing and another brought to the gate in its place. This would take a while. Those of us in the departure lounge settled in for what we suspected might be hours. From the window I watched the ground crew unload the bags from the original airplane. When the new one arrived, the crew pumped the fuel, loaded the bags, and stocked the galley. It was a scene I’d witnessed countless times. Soon we would board and be on the way to our destinations.

As for the first airplane, the one with the maintenance problem—what was its destination going to be? When you have time on your hands, you begin to wonder about things like this. My own assumption, as yours might have been, was that the aircraft would be towed to a nearby hangar for a stopgap repair and then flown to a central maintenance facility run by the airline somewhere in the U.S. Or maybe there was one right here at the airport. In any case, if it needed a major overhaul, presumably it would be performed by the airline’s staff of trained professionals. If Apple feels it needs a “Genius Bar” at its stores to deal with hardware and software that cost a few hundred dollars, an airline must have something equivalent to safeguard an airplane worth a few hundred million.

About this I would be wrong—as wrong as it is possible to be. Over the past decade, nearly all large U.S. airlines have shifted heavy maintenance work on their airplanes to repair shops thousands of miles away, in developing countries, where the mechanics who take the planes apart (completely) and put them back together (or almost) may not even be able to read or speak English. US Airways and Southwest fly planes to a maintenance facility in El Salvador. Delta sends planes to Mexico. United uses a shop in China. American still does much of its most intensive maintenance in-house in the U.S., but that is likely to change in the aftermath of the company’s merger with US Airways.

The airlines are shipping this maintenance work offshore for the reason you’d expect: to cut labor costs. Mechanics in El Salvador, Mexico, China, and elsewhere earn a fraction of what mechanics in the U.S. do. In part because of this offshoring, the number of maintenance jobs at U.S. carriers has plummeted, from 72,000 in the year 2000 to fewer than 50,000 today. But the issue isn’t just jobs. A century ago, Upton Sinclair wrote his novel The Jungle to call attention to the plight of workers in the slaughterhouses, but what really got people upset was learning how unsafe their meat was. Safety is an issue here, too. The Federal Aviation Administration is supposed to be inspecting all the overseas facilities that do maintenance for airlines—just as it is supposed to inspect those in America. But the F.A.A. no longer has the money or the manpower to do this.

One of the fastest-growing of the offshore repair sites is on the perimeter of El Salvador’s Monseñor Óscar Arnulfo Romero International Airport. Named for the archbishop who was assassinated during Mass in 1980, the airport has become a busy hub, owing largely to a steady influx of foreign jetliners needing maintenance and repair. Jets flying the insignia of US Airways, Southwest, Jet Blue, and many smaller American carriers are a common sight as they touch down and taxi to the Aeroman complex at the edge of the field.

Aeroman was once the repair base for El Salvador’s modest national airline. It has mushroomed into a complex of five hangars, 18 production lines, and numerous specialty shops that perform virtually all phases of aircraft overhaul. The company has picked up the familiar multi-national technobabble, describing itself as a “world leader in providing aircraft-maintenance solutions.” About 2,000 mechanics and other employees work in the company’s tightly guarded airport compound, encircled by a fence and barbed wire.

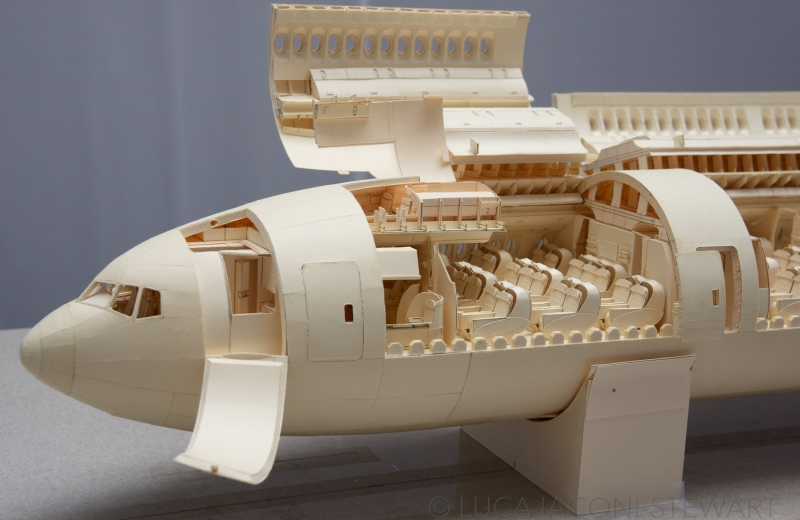

The airplanes that U.S. carriers send to Aeroman undergo what’s known in the industry as “heavy maintenance,” which often involves a complete teardown of the aircraft. Every plate and panel on the wings, tail, flaps, and rudder are unscrewed, and all the parts within—cables, brackets, bearings, and bolts—are removed for inspection. The landing gear is disassembled and checked for cracks, hydraulic leaks, and corrosion. The engines are removed and inspected for wear. Inside, the passenger seats, tray tables, overhead bins, carpeting, and side panels are removed until the cabin has been stripped down to bare metal. Then everything is put back exactly where it was, at least in theory.

The work is labor-intensive and complicated, and the technical manuals are written in English, the language of international aviation. According to regulations, in order to receive F.A.A. certification as a mechanic, a worker needs to be able to “read, speak, write, and comprehend spoken English.” Most of the mechanics in El Salvador and some other developing countries who take apart the big jets and then put them back together are unable to meet this standard. At Aeroman’s El Salvador facility, only one mechanic out of eight is F.A.A.-certified. At a major overhaul base used by United Airlines in China, the ratio is one F.A.A.-certified mechanic for every 31 non-certified mechanics. In contrast, back when U.S. airlines performed heavy maintenance at their own, domestic facilities, F.A.A.-certified mechanics far outnumbered everyone else. At American Airlines’ mammoth heavy-maintenance facility in Tulsa, certified mechanics outnumber the uncertified four to one. Because heavy maintenance is labor-intensive and offshore labor is cheap, there’s a perception that the work is unskilled. But that’s not true. If something as mundane as the tray of a tray table becomes unattached, the arms that hold it could easily turn into spears.

There are 731 foreign repair shops certified by the F.A.A. around the globe. How qualified are the mechanics in these hundreds of places? It’s very hard to check. In the past, when heavy maintenance was performed on United’s planes at a huge hangar at San Francisco International Airport, a government inspector could easily drive a few minutes from an office in the Bay Area to make a surprise inspection. Today that maintenance work is done in Beijing. The inspectors responsible for checking on how Chinese workers service airplanes are based in Los Angeles, 6,500 miles away.

Lack of proximity is only part of the problem. To inspect any foreign repair station, the F.A.A. first must obtain permission from the foreign government where the facility is located. Then, after a visa is granted, the U.S. must inform that government when the F.A.A. inspector will be coming. So much for the element of surprise—the very core of any inspection process. That inspections have had the heart torn out of them should come as no surprise. It is the pattern that has beset the regulation of drugs, food, and everything else.